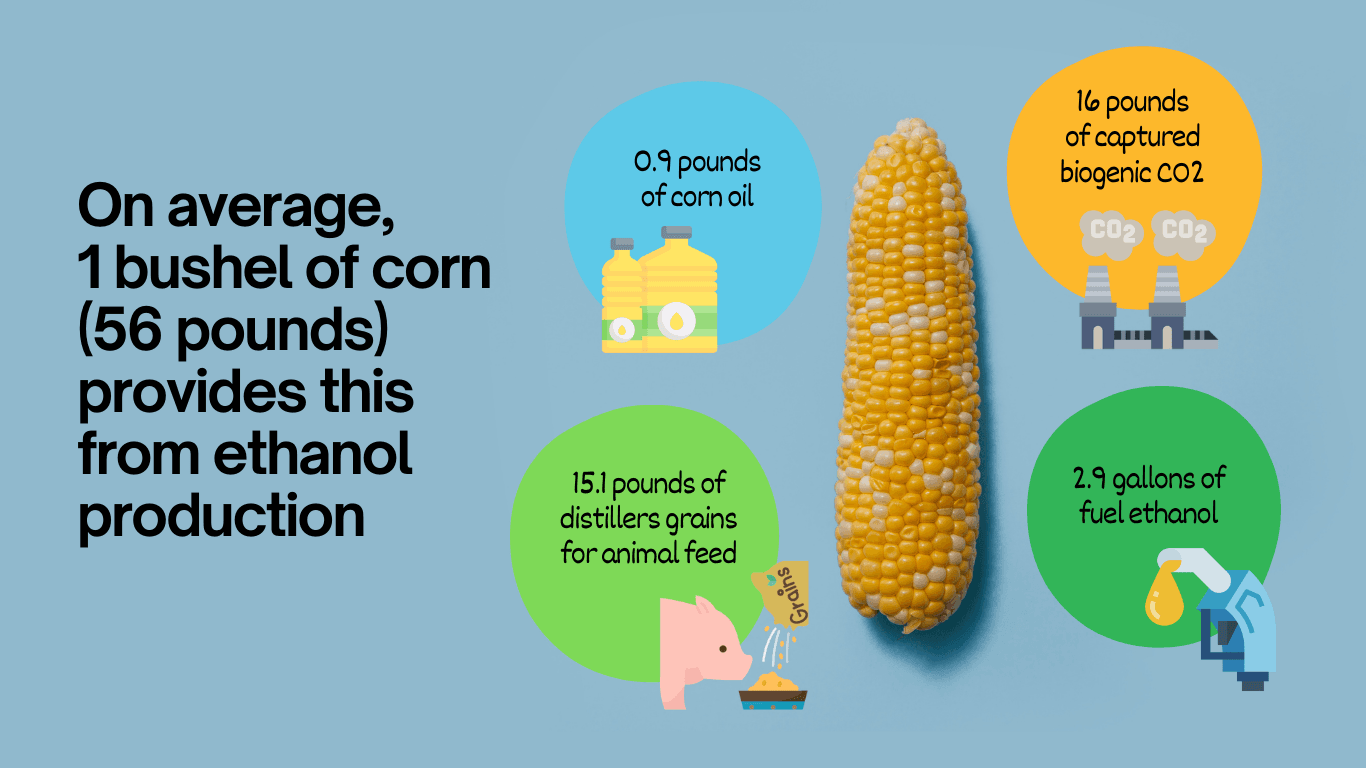

Beyond its role as a clean and renewable fuel, ethanol production generates several valuable co-products.

Distillers Grains: After the fermentation process, the remaining grain material is used to create dried distillers grains (DDGs). This nutrient-rich co-product serves as an excellent livestock feed, providing a sustainable and protein-rich alternative for animal nutrition.

Additionally, feeding DDGs to cattle generates an economic benefit of more than $900 million to Nebraska each year. Thanks to feeding trials sponsored in part by the Nebraska Ethanol Board, DDGs and corn gluten feed have become widely accepted among Nebraska’s beef producers as a preferred ingredient in their animal rations. In fact, DDGS have replaced soybean meal as the second largest livestock feed component behind corn.

Corn Oil: This nutrient-dense oil has various applications, including biodiesel production and as a feedstock for animal nutrition. The remaining condensed solubles are used to produce syrup and added back into the distillers grains to increase the feed's nutritional value.

Carbon Dioxide (CO2): Ethanol production is a source of high-purity carbon dioxide (CO2). This co-product finds applications beyond the ethanol plant in industries such as food and beverage, where it is used in carbonation, food processing, and as a cooling agent. The utilization of CO2 as a co-product minimizes waste and enhances the overall efficiency of the ethanol production process.

By extracting additional value from the production process, ethanol facilities contribute to a more sustainable and circular economy.